Design

Manufacture

Digital print & Vinyl

Finishing

Assembly

Delivery

Design

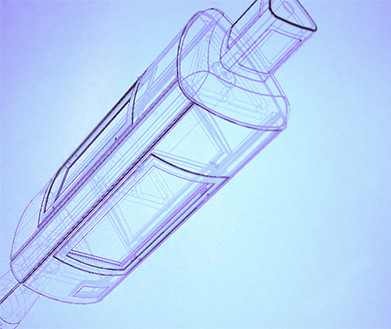

Specification to the very last detail.

To get every detail, every curve and contour just right during signage manufacture, we first take the time to think about the way each sign is going to look when it’s finished. Additionally, we consider every angle, every material used, because how a sign is made is every bit as important as how it looks.

Our design and engineering processes

Working with AutoCAD and Solidedge software, our designers issue our production team with complete specifications for design. This means manufacture has been carefully thought out before any work is done. Customer specification and brand guidelines are taken into consideration, ensuring smooth and efficient production at the highest quality.

So you can rest assured that your clients will receive exactly what they’re expecting.

Manufacture

Intricately made on a massive scale.

Every sign is efficiently manufactured to meet time-sensitive demands on a large scale, without sacrificing precision, quality and an obsessive attention to detail. This makes satisfying clients’ needs all the more simple.

Signage manufacture processes

Our full in-house facilities allow us to complete signage manufacture quicker and at higher volume. These include Bystronic 4x2m Fibre 4kw Laser, AXYZ routers, 4m and 3M Bystronic CNC press brakes, 3m long rollers, letter bending machine, punching machines, tig, mig and synergic welding capabilities. Experienced metal, acrylic and aluminium composite fabricators oversee the work throughout.

That’s why you can be sure that clients’ expectations will be met, because all our signage products are made to the absolute highest level of quality, however big or small.

Digital print & Vinyl

Graphical finish that is pixel-perfect.

For graphic signage and display, digital vinyl print is applied to create an image that is visually striking and conceptually on-point. Right down to the very last pixel.

Our digital print and vinyl processes

Our in-house digital print facilities include a Summa Plotter, Rolls Roller, Easymount Laminator, Mimaki UCJV300-160 UV and HP Latex wide format printers, operated with Mimaki Rasterlink 7 RIP software & Onyx. This allows for high-quality graphics that can be quickly added as part of our manufacturing and finishing processes.

With the aid of sophisticated graphics and imaging software, we can apply most images, without hassle, for ultimate client satisfaction.

We use a 5-7 year Image Perfect print media unless otherwise specified.

Finishing

No sign is finished, until it’s finished.

With Gloss, Satin or Matt finish as standard, all our signage products are given the desired look to create something visually impressive. Because at the end of the day, no signage manufacture process is complete until the finishing touches are put into place.

Finish options

In addition to standard finish options, we also offer our unique gradiated paint finishing. This allows seamless colour transition with fully gradiated powder coating. As well as anti-vandal lacquer which provides added protection.

To create the perfect metallic look we offer products in stainless steel, polished to either mirror or brushed finish. We also have access to elegant architectural materials from Rimex, for an effect that is both stunning and refined.

Our coating & painting processes

In order to optimise efficiency and production quality, we’ve invested considerable efforts modernising our in-house powder-coat and painting facilities. This includes the ability to colour in powder or wet spray to all standard RAL and BS4800 colours. We are also able to match to Pantone PMS colours*. Whilst clear acrylic panels are flame polished to complete the finished effect.

Above all, our upgraded facilities boast an impressive 5m x 3.5m oven and an 8m x 5m wet spray booth, allowing for increased capacity and the ability to coat larger products. It’s all about working to a production schedule that meets the needs of our customers and their clients, without compromising on the high standard of quality NCS have come to be known for.

*Colour match to Pantone colours are not guaranteed.

Assembly

Meticulously put together, with purpose and precision.

Assembly is more than just an afterthought, it’s an integral part of what we do. That’s why every sign we produce is carefully put together, piece by piece, with real consideration for purpose and the greatest level of precision.

Illumination. Acrylics. Back frames. Every component is expertly and securely fitted by our experienced sign assembly team. Each sign is checked before it is packaged ready for dispatch.

All lighting is electrically tested and provided with a certificate. Therefore, when your signage order arrives, you can hand it over to your client with the highest level of confidence.

Delivery

Sign, sealed, delivered. Whatever your preference.

We provide a number of delivery options, which will be discussed with you by a member of our contracts team.

So if you prefer, we can get your signage delivered to you via one of our drivers in one of our unmarked vans, via a designated courier, flatbed lorry or hi-ab. Alternatively, we can arrange for an overnight carrier to deliver smaller items.

In short, we endeavour to help you fulfil your role as a supplier of quality signage products, as and when your clients need them.